|

|

|

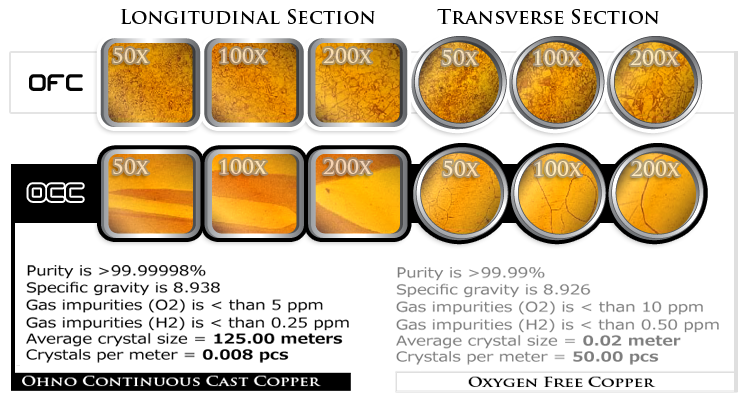

Why OCC? Used throughout the high end audio industry in most flagship cable products, occ provides the superior quality copper and silver possible today. OCC (Ohno Continuous Cast) is the name given to the casting process developed to help defeat annealing issues and virtually eliminate all grain boundaries in copper or silver with a unique patented process. The OCC casting method uses specialized heated moulds in order to draw a single crystal up to 125 meters in length. With only a single crystal in very long lengths, there is an unimpeded free path for the best possible signal transfer. Along with this superior single long crystal structure, OCC provides copper and silver with the least possible oxides and other impurities. In high contrast to OCC, there are other lower grade coppers such as OFC with a multitude of grain boundaries and other impurities. OFC (Oxygen Free Copper) has around 400 crystals per foot and despite its name has an oxygen content of about 10 ppm. Having less oxygen content and less overall impurities compared OFC. OFC has a plethora of grain boundaries per foot that the signal must route around and pass. |

|

| The question ultimately comes down to the following: Would you rather have your signal flow in a path with many cracks, bumps and obstacles in the way (OFC) or flow along an unimpeded free path with the lowest possible impurities (OCC). From our view the choice is simple, and the bottom line is most top cable designs utilize OCC as it gives the absolute purest base platform to get that much closer to true absolute transparency. |

|

OCC (ohno continuous cast): The purest copper and silver on planet Earth. Litz: The top design for eliminating skin and proximity effect Litz: The strongest and most durable conductor design Litz: The top design for eliminating degradation from oxidation

OCC (Ohno Continuous Cast) + Fine Stranded Complex Litz The most dominant and sonically the most transparent cable. Contact "headphonecables at norneaudio dot com" for pricing and ordering information. |